Disc-Style Whole Tree Drum-Style Whole Tree

Why Buy a Bandit Whole Tree Chipper?

A complete range of chipper models

Bandit Industries, Inc. manufactures an array of whole tree chippers designed to excel at chipping large diameter material using less horsepower and fuel. Most of these units are being used in a variety of biomass operations, converting whole trees, tops, and diseased wood into chips for fuel. They are also an excellent choice for land clearing operations, right-of-way clearing contractors, loggers, and tree services.

“Disc vs. Drum: Bandit Gives You A Choice”

“Disc-Style Chippers”

Trelan by Bandit Disc-style chippers chip material at an approximate 45º angle, allowing it to be chipped with the grain of the wood. This set-up has the following advantages:

*** The angled feed requires less horsepower to chip larger diameter material.

*** Chipping on an angle is similar to whittling, allowing the machine to use less fuel and reduce vibration.

*** Cupped throwers attached to the disc capture and throw chips out of the discharge at a tremendous velocity, fully compacting full-length chip trailers.

*** Can produce a high quality chip ranging from 3/4″ to 1 1/8″.

“Drum-Style Chippers”

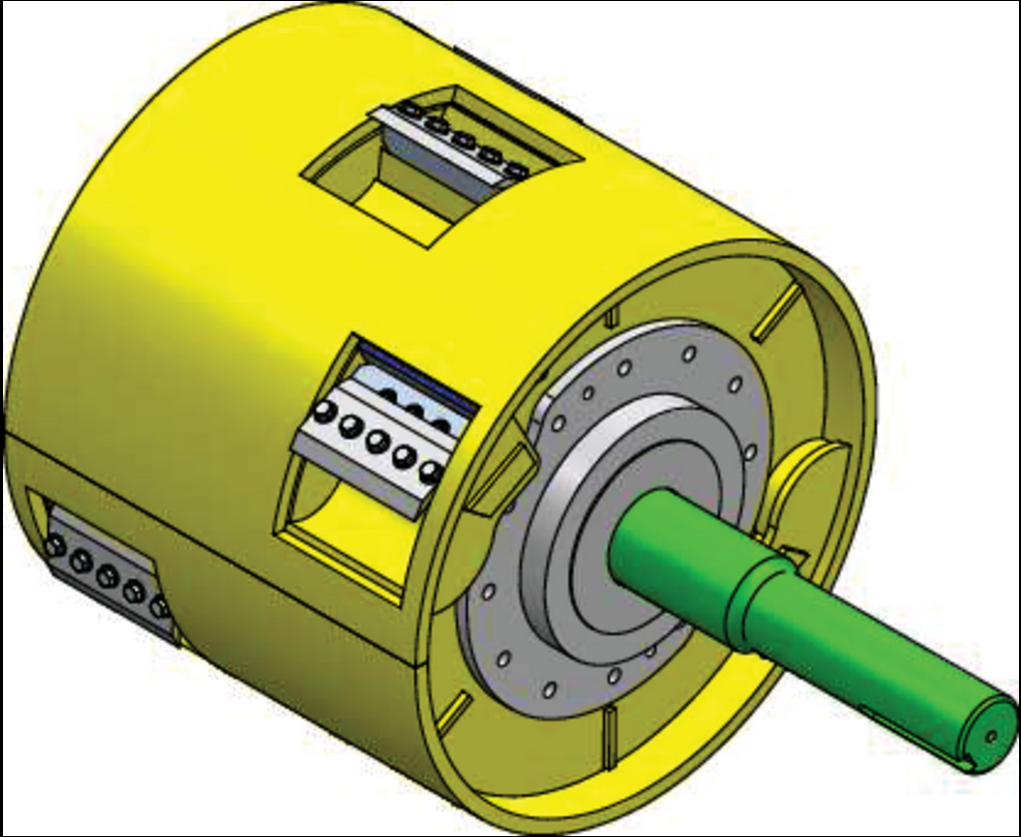

Bandit drum-style chippers feature heavy-duty reinforced drums, which is why they are offered with an industry leading 5 year “GUTS” warranty. Advantages of a drum-style chipper include:

• The feed system is more closely coupled to the drum, allowing the chipper to effectively collapse limbs.

• The throat openings on drum-style chippers are larger, allowing them to process more material at one time.

• Drum chippers will process more fibrous materials found in warmer climates, and are the machine of choice for those companies consistently chipping tops.

“Fuel Efficient”

All Bandit whole tree chippers are extremely fuel-efficient. Recent data collected from a larger Bandit whole tree drum chipper processing hardwood for fuel chips used around one gallon of fuel per five tons of chips. The powerful feed systems and smooth discharge transitions allow all Bandit whole tree chippers to easily process larger diameter and/or limby material, thereby reducing fuel consumption.

“Durable Construction”

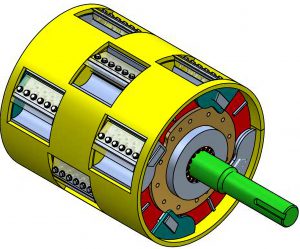

All Bandit drums are built with 1″ thick drum skins and numerous internal baffles reinforce the drum. As an example it takes 70 hours to weld a 3590 drum together. The throat housing, drum bases, infeed and discharges are all constructed of AR400 and T1 steel.

No bolt-together components are used. For these reasons, all Bandit whole tree chippers come with a five-year “GUTS” warranty covering the Bandit components on the Slide Box Feed System and disc or drum.

“Slide Box Feed System”

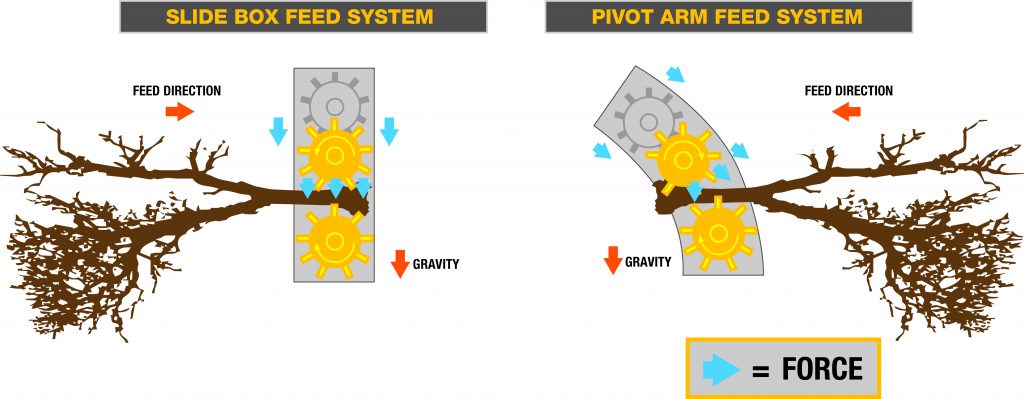

Bandit whole tree chippers feature the most powerful, durable feed systems available on the market today, thanks largely to the Slide Box. As the material passes through the feed system and into the chipper, the Slide Box allows the top feed wheel(s) to flow straight up and down. This trouble-free system for carrying the top feed wheel(s) allows direct down-pressure for crushing material and is also applied through the hydraulic lift cylinders (standard). The power of the chain-driven feed wheels combined with powerful hydraulic motors generate an enormous amount of torque for maximum compressing and pulling power. Loading material into the chipper is simple and quick, and operators can easily feed large diameter whole trees with few hang-ups. Notice in the below diagram (right) how the slide box feed system provides direct down pressure on material as it enter the feed system compared to the (left) picture showing a pivot arm which does not allow for direct down pressure.

“Multiple Wheel Feed Systems”

All whole tree chippers feature powerful dual feed systems for compressing limbs and branches. These feed systems easily pull large diameter whole trees into the chipper. All of the Bandit feed systems have at least a top and bottom feed wheel. The 3090 and 3590’s can be ordered with side mounted vertical feed wheels for additional pulling power. The multiple wheel feed system is considered to be the best feed system ever developed for a whole tree chipper.

“Infeed Conveyors”

Infeed conveyors are available on all Bandit whole tree chippers. These long infeed conveyors, with heavy-duty track style conveyor chain, simplify the feeding of limby material, shorter pieces, and piles of brush. These conveyors also provide additional pulling power to assist in pulling material into the chipper. In addition, the infeed conveyors slope, making it easier to feed whole trees.

“Chip Throwing Power”

The unique design of the pockets in our drum chipper, smooth transitions and unrestrictive discharges enhance the throwing power of the chipper. Another key feature is our patented power slot that provides additional air intake where it is needed the most on the backside of the chipper housing. The power slot eliminates the possibility of a vacuum within the drum housing that could slow the flow of chips from the chipper. The power slot also allows debris to fall from the housing as the machine is being shut down, keeping the material from lodging in the belly of the chipper, making it easier to start the drum. The power slot also makes it easier to dislodge material from the discharge should the discharge plug. Cleanout doors also assist in preventing the discharge from becoming plugged.

“Knife Options”

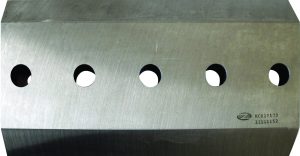

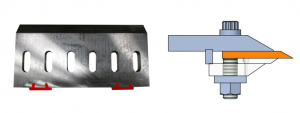

Bolt-in or babbitted knives are available on most Bandit whole tree chippers. Bolt-in knives are usually utilized by those companies not needing a specific chip size. The babbitted knife set-up is often used and is the preferred choice if a specific chip size is needed for pulp, paper, or wood fuel plants. The chip size can be set at 3/4″, 7/8″, or 1″.

“Reversing Auto Feed System”

All Bandit whole tree chippers come standard with our Reversing Auto Feed. This system eliminates the need for an operator to stop the feed system to allow the engine to recover once it loses RPM. Reversing Auto Feed minimizes chip plugging, increases knife life, improves chip quality, and improves fuel economy by backing the material out of the cut.

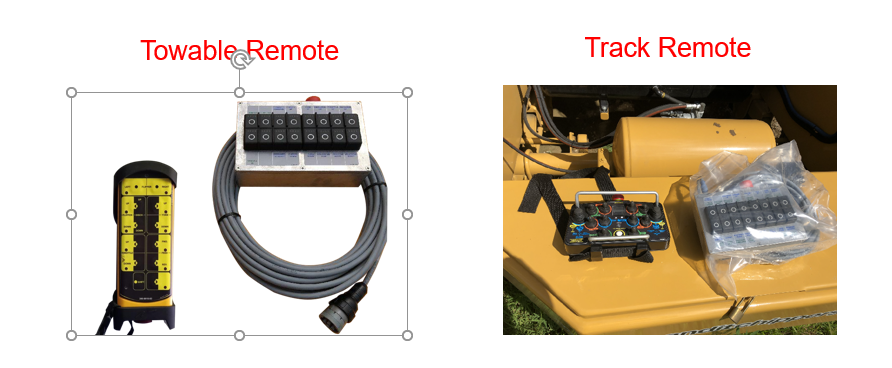

“Radio Remote Control”

A wireless radio remote with tether back-up is standard on all towable and track units without cab and loader. The remote will control chipper feed system, discharge functions and tracks if applicable.

“Chip Size is Important”

We offer drums that will produce a standard 3/4″ chip and an oversized 1-½” chip, and a drum that will produce a 3/16″ or ¼” micro chip.

Standard Drum: The standard drum that produces a ¾” chip is set up to make two cuts per revolution when making a more common ¾” chip.

Maxi Chips: Using a typical Bandit drum, half of the knives are removed and the remaining knives are extended to make one cut per revolution. This knife arrangement produces a larger, 1-½” maxi chip. Maxi chips are popular for certain top- or center-loading fluidized boilers, for metallurgical use and in the production of charcoal.

Micro Chips: Featuring double the number of cuts per revolution, the micro chip drum can produce either a micro chip or standard chip. Switching between standard and micro chips is as simple as removing half of the knives and adjusting the remaining knives.

[Micro Chip Drum Head]

The Micro Chip Drum Head is offered on the 2590, 3090 & the standard 3590. The drum head makes four cuts per revolution, with 3/16″ chip size being the standard. The Micro chip drum will fit in most previously built chippers, however, other adjustments are required when updating a previously built chipper.

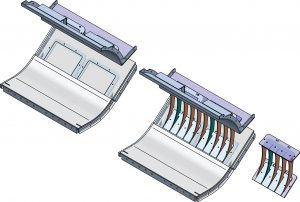

[Chip Screen/Card Breaker]

The Chip Screen/Card Breaker system is currently available on the 2590, 3090, 3590 and 3590XL. Constructed out of wear-resistant material, this system restricts oversized material from flowing through the chipper until properly sized. Because Bandit chippers have such aggressive throwing power, the Card Breaker System further reduces oversized chips by literally breaking them as they enter the discharge chute. This system significantly enhances the uniformity of the end product for any chip size configuration. The breaker system is bolt-in, which allows it to be replaceable and this feature can be added to a previously-built chipper.

Popular Options for Bandit Whole Tree Chippers

Fully Customize Your Machine

As with all Bandit products, a wide variety of options are available for our whole tree chippers. These options will simplify a wide variety of applications and should be presented to your customers when they are looking at purchasing a piece of equipment.

“Rotobec Cab and Loader”

Select Bandit whole tree chippers can be equipped with a cab and loader option from Rotobec. This option is an excellent choice for tree services, loggers, and land clearing operations that do not have a separate loader to feed the chipper. The loader is extremely durable and features a grapple rotator and heavy-duty turntable bearing. All cabs are designed for maximum operator comfort, featuring plenty of window space and deluxe seat with armrest and joystick controls.

[Steel Track Undercarriage]

Caterpillar steel track undercarriages can be added to all Bandit whole tree chippers. This feature allows them to travel over rough terrain not accessible by towable units. It also eliminates the need to forward or skid material to the chipper. Instead, the operator can take the chipper to the trees.

• Track unit with cab and loader (2290 only): All track and loader functions are controlled from a roomy Operator’s cab. The Operator’s cab features a comfortable swivel seat, joystick controls, and heater and A/C system.

• Track unit without cab and loader: Track and chipper functions are controlled by a radio remote control, allowing the operator to maneuver the chipper from a remote location, or from a loader feeding the unit.

“Air Compressor”

An 11-horsepower air compressor with 24 gallon air tank is available as an option. This serves as a useful option to assist with blowing debris off of the machine after a day’s work. It also can be utilized to run an air impact wrench to help make knife changing quicker. Please remember that the air impact can be used to tighten the knife bolts down, but a torque wrench MUST be utilized per the operator’s manual instructions to ensure proper torque.